The flour most of us are familiar with—the inert, white powdery stuff from the supermarket with a long shelf life—is a very modern development in our long relationship with wheat, the most important food in history. Before industrial agriculture became dominant, milling was done at regional mills with diverse strains of wheat. The effort to create uniform flours that won’t spoil has taken much of the flavor and nutrition from our flour and the products made with it.

The flour most of us are familiar with—the inert, white powdery stuff from the supermarket with a long shelf life—is a very modern development in our long relationship with wheat, the most important food in history. Before industrial agriculture became dominant, milling was done at regional mills with diverse strains of wheat. The effort to create uniform flours that won’t spoil has taken much of the flavor and nutrition from our flour and the products made with it.

One of the national leaders in the effort to restore flavor and nutrition to available wheat is located just north of Seattle in the Skagit Valley. Dr. Steven Jones runs The Bread Lab, an extension of Washington State University. He is devoted to bringing grain agriculture back to our region. A hundred years ago, fields of grains filled the Skagit Valley, but as industrial wheat brought the price of the commodity down farmers shifted to more valuable crops. Recently though, farmers, using wheat as a rotation crop to break disease cycles and to restore vital elements to the soil have discovered, or rediscovered, that many varietals grow wonderfully there. This is where The Bread Lab comes in. Jones is a wheat breeder dedicated to making regional grain farming viable again. His lab develops vigorous wheat hybrids full in flavor and nutritional value that grow optimally in particular climates.

Over six years ago, I was invited to be part of The Bread Lab’s advisory board. Back then I had no idea how impactful it would be. At the time, I was happy with our flour and didn’t imagine I would be looking elsewhere. A few bakers I knew in Seattle were experimenting with milling their own flours. I was eager to learn more. The Bread Lab proved to be an excellent resource. It gave me the opportunity to test wheat from smaller growers. Jones and his team check it for strength and provide us with its falling number, which indicates the speed of fermentation. As you can imagine, our baking schedule is pretty tight. A dough moving unexpectedly slowly or quickly can really throw things off.

Using ingredients with the highest integrity has always been central to my mission at Macrina. In flours, flavor and high nutritional value are the two most important things I look for, along with consistency and a reliable supply. My earliest fascination was with whole grain milling. Most commercially produced flour is made only with the starchy endosperm of the grain. Both the nutrient-rich bran and flavorful wheat germ are discarded because the oils they contain will turn rancid in a few weeks. But the durability that commercial flour gains by discarding them comes at an enormous cost—the loss of flavor and nutrition.

This is why, years ago, I started using freshly milled whole grain flours from Fairhaven Mills. I admire the nutty and natural caramel flavor that comes from the milled whole grain flours. When I first started experimenting with this whole grained milled flour, I was hydrating a portion of the flour to soften the bran. This worked to some degree, but I was still not getting the rise I wanted, resulting in a dense texture. The Bread Lab provided me with many strategies. With their help and plenty of experimenting, I got the results I desired. On another occasion, we had a difficulty with a flour we were getting from Fairhaven Mills. They’d had to substitute a wheat from Montana rather the Walla Walla wheat we’d been using. I sent a sample to The Bread Lab. They tested it and determined that the wheat had a smaller falling number, which means the dough develops quickly. We reduced the mixing time and with lots of tweaking got consistent results. When you’re mixing hundreds of pounds of dough destined for someone’s table in a few hours and the dough isn’t behaving you can imagine the frenetic scene that results.

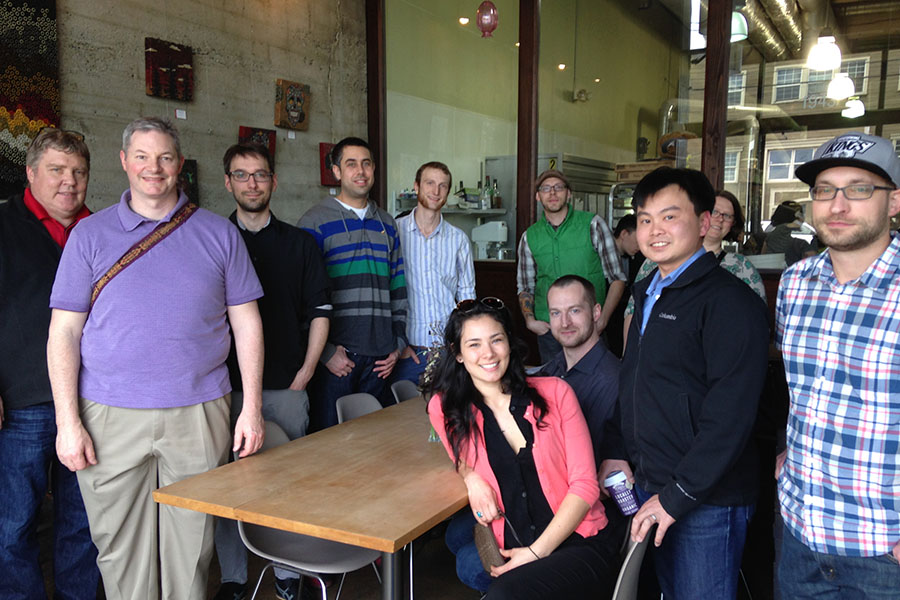

Every year The Bread Lab hosts an annual conference called Grain Gathering. Professional bakers, bread enthusiasts, brewers, farmers, and chefs from around the country descend on the Skagit Valley. Workshops, panel discussions, and demonstrations cover a range of wheat-centered topics (I’ve learned lots from these over the years). At the 2015 event, they held a bread tasting for a group of experienced bakers. We tasted seven breads, each made with a different locally grown wheat. For each loaf the recipe was essentially the same, with small adaptations made to create the best loaf with each flour. The varying tastes, textures, and the overall natural sweetness was a revelation. The flour made all the difference. The experience inspired my commitment to bringing more locally grown flours to the breads we make at Macrina.

Every year The Bread Lab hosts an annual conference called Grain Gathering. Professional bakers, bread enthusiasts, brewers, farmers, and chefs from around the country descend on the Skagit Valley. Workshops, panel discussions, and demonstrations cover a range of wheat-centered topics (I’ve learned lots from these over the years). At the 2015 event, they held a bread tasting for a group of experienced bakers. We tasted seven breads, each made with a different locally grown wheat. For each loaf the recipe was essentially the same, with small adaptations made to create the best loaf with each flour. The varying tastes, textures, and the overall natural sweetness was a revelation. The flour made all the difference. The experience inspired my commitment to bringing more locally grown flours to the breads we make at Macrina.

One of the challenges The Bread Lab faces is that making local wheats prevalent takes more than introducing them to local bakers. Local grain economies that existed before the mass produced flours drove them out of business must be rebuilt. That includes persuading farmers to grow the grains, mills to grind them, stores to sell them and buyers to purchase them. Contributing to a healthy and sustainable local food economy is not just a good thing for Macrina to do, it’s a great thing for our bread. You just can’t beat the taste that freshly milled whole grain flours provide.

With the success The Bread Lab has experienced they’ve outgrown their small space and this summer will relocate to a 12,000-square-foot building. King Arthur Flour is partnering with them to add a full-scale mill and educational center. The state-of-the-art facility, and the passion and knowledge of Jones and his team, is a unique treasure. We are lucky to be so close to the innovation taking place in Skagit Valley, innovation with benefits that extend through the state and beyond.

Leslie