Not only am I fan of their coffee, I admire Herkimer’s employee-driven focus. It shows in the quality of their product and service. If you don’t already know them, drop by one of their three locations. You won’t be sorry. —Leslie.

Third wave coffee refers to the direct trade, farmer-obsessed purists, many of whom feature lightly roasted single-origin coffees best brewed with a slow-motion pour over. Stumptown, Blue Bottle, and Intelligentsia Coffee are three of the big ones. All have recently taken on large investors and big expansion plans are underway. Their founders are living the dream.

But what of those who dream differently?

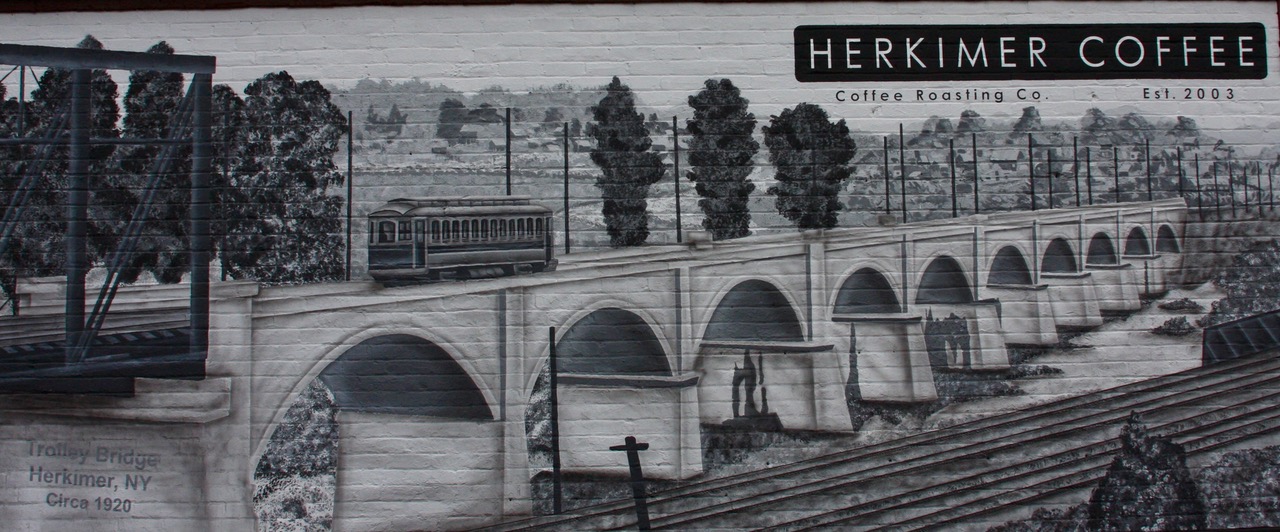

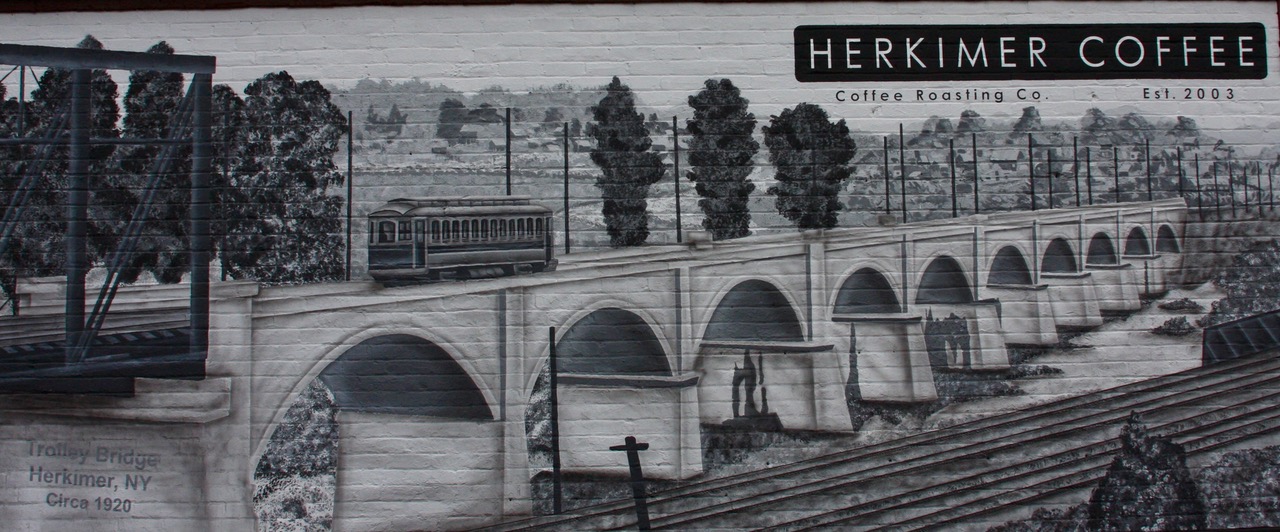

Herkimer Coffee, founded in 2003, roasts exquisite coffees but prefers to stay small. Mike Prins, the owner and founder of Herkimer coffee, named the business after the town in upstate New York where his father was born. For him, Herkimer Coffee is about roots and simple dreams. It’s about values that run deep. It’s a place where relationships are more important than profit and the only palpable marketing plan is to make an authentic, high-quality product.

Herkimer Coffee probably wouldn’t exist had Mike not gotten a do-over.

Back in the early 90’s, while working for a Seattle company that sold and repaired espresso machines, Mike visited B&W Specialty Coffee, a small roaster in Minneapolis. “I wanted to open a small café that roasted its own coffee, but it seemed unattainable. Then on this business trip, I met the folks at B&W who were young and making great coffee in a small-batch roaster. The main thing I remember is their passion and how much fun they seemed to be having. It was just a brief visit, but it sparked a dream.”

In 1994, Mike opened Caffe Vita on Queen Anne with a partner. Their little café took off, and in 1995 they began roasting. By 2002, the business had flourished. But it wasn’t that little roaster on the corner anymore. Mike sold his stake in the business.

“I thought I’d left coffee for good,” Mike says. “I was in limbo, no job, not sure what would come next. Some months later, walking home from the store in my Greenwood neighborhood I noticed a corner building with a For Lease sign in the window. That’s a good spot, I thought. I made a phone call and away it went.”

This time though he wasn’t going to let the dream get away from him. Herkimer Coffee, whatever it would become, would remain small and sustainable, and it would focus on relationships with employees and customers. And most importantly it would be a place he enjoyed coming to each day.

“This place is really well thought out,” Candace Harter, the Greenwood café manager, says. “We focus on traditional coffee bar fare. Espresso drinks and drip coffee. We don’t try to do too much. We use Macrina products and Mighty-O donuts. It allows us to focus on what we do well, serving coffee to the community.”

Mike started the café using coffee roasted by Caffe Vita. That changed in 2007 when he added a roaster in the space adjacent to the café. Mike then brought on Scott Richardson to buy green coffee, to roast, and to be the wholesale manager.

“Scott and I go back to 1996, Kara, too,” Mike says (Kara MacDonald was the first hire at Herkimer and now runs the Ravenna shop). “We all worked together back in the Vita days. Scott was roasting and overseeing wholesale while Kara was managing retail.”

Much has changed in elite specialty coffee since then. In the mid-nineties, Seattle was in the midst of the European-inspired, espresso-oriented second wave. (The first wave occurred in the early twentieth century with the establishment of national brands like Maxwell House and Folgers.)

“When I started sourcing coffee for Herkimer I wanted to take it to another level,” Scott says. “I wanted to know the producers. The old style was to buy the best coffee on the commodity market at the lowest price. But that’s not very fair to the grower, nor does it get you the finest coffees.”

Scott now travels to source countries frequently and purchases much of Herkimer’s green coffee directly from the producer. “My interest is a long-term reciprocal relationship. Farmers come out better, we can both budget, and I can count on excellent coffee.”

Some of that coffee goes into single-origin roasts. But most of it is blended for espresso. “Seatle was born as an espresso-driven market. And it still is,” Scott says. “Old world aesthetic means I love a big, gooey espresso. One with high oil saturation, high carbohydrates, good acid balance, but not sour. Too many pull acidic espresso with light roasts. Those light roasts are great in a pour over, but as espresso they’ll curdle milk. I like where espresso comes from, its history, everything about it. I go out of my way to source coffee from very high elevations. The coffees I put in our espresso blend have what it takes to make them big and balanced, a coffee you won’t get sick of drinking every day.”

Herkimer’s quality is a function of relationships: relationships with employees, with customers at the coffee bar, with wholesale accounts, and with coffee producers.

“We have 24 employees, including myself,” Mike says. “Over a third have been here more than five years, and many more than ten. That’s pretty unique. I try to put everyone in a position where they can succeed at what they like to do.”

Choosing the right person for the job is like choosing the right coffee. The wrong one can sour the blend.

Two early employees, Nathan Reasoner and Reid Hickman, both worked at Zoka before coming to Herkimer soon after the roastery opened. They both roast and help with sales. In addition, Reed built and manages the company website. Nathan manages the wholesale accounts.

“Now that the third wave, the premium farmer-focused coffee movement, is getting a lot bigger it puts us in an interesting position, trying to manage our own growth and retain what makes our coffee special,” Reid says. “We find these small lots that are beautiful. We have great people roasting. If we grow too fast we wouldn’t be able to source enough of the best coffees or find and train the right people to roast and prepare it.”

“Now that the third wave, the premium farmer-focused coffee movement, is getting a lot bigger it puts us in an interesting position, trying to manage our own growth and retain what makes our coffee special,” Reid says. “We find these small lots that are beautiful. We have great people roasting. If we grow too fast we wouldn’t be able to source enough of the best coffees or find and train the right people to roast and prepare it.”

“We’re lucky to be in an environment, around people we enjoy, doing something that we like,” Nathan says. “I wanted to find a career where I could have a good life and make something I’m proud of. In this day and age, in this city, that’s hard to find.”

Mike says, “People make strange decisions that aren’t always the best when they’re trying to grow too fast. For us, quality of life is the most important factor in our growth decisions. We want to continue to do for our customers and staff all that we say we are going to do. That’s very important to us.”

This focus on relationships is the beating heart of the extended Herkimer community, on both sides of the coffee bar, with the wholesale buyers, and with the coffee producers.“I like coming to work every day,” Mike says. “I like being around all the great people we have. I love coffee. Those are boring statements, but it’s what I enjoy.”

Herkimer Coffee has locations in the Queen Anne, Phinney Ridge and Ravenna neighborhoods. Find out more at https://herkimercoffee.com/.

“Now that the third wave, the premium farmer-focused coffee movement, is getting a lot bigger it puts us in an interesting position, trying to manage our own growth and retain what makes our coffee special,” Reid says. “We find these small lots that are beautiful. We have great people roasting. If we grow too fast we wouldn’t be able to source enough of the best coffees or find and train the right people to roast and prepare it.”

“Now that the third wave, the premium farmer-focused coffee movement, is getting a lot bigger it puts us in an interesting position, trying to manage our own growth and retain what makes our coffee special,” Reid says. “We find these small lots that are beautiful. We have great people roasting. If we grow too fast we wouldn’t be able to source enough of the best coffees or find and train the right people to roast and prepare it.”

For such a small, artisan producer news of her remarkable jam has spread from coast to coast through national press, including the New York Times. Web orders from across the country have filtered in and a few small business owners enchanted with the jam and Washington small-farm agriculture now retail the colorful hexagonal jars of jam.

For such a small, artisan producer news of her remarkable jam has spread from coast to coast through national press, including the New York Times. Web orders from across the country have filtered in and a few small business owners enchanted with the jam and Washington small-farm agriculture now retail the colorful hexagonal jars of jam.